Copyright © 2025 FACTON

CONTENT

Optimize your supply chain with should cost analysis - reduce expenses, better understand supplier cost structures, and achieve profitability with actionable insights.

Why purchasing and cost engineering need should costing

WHAT IS A SHOULD COST ANALYSIS?

Should cost analysis, also known as should costing or cost breakdown analysis, is a method for determining the cost of a product or service.

By breaking down a product's cost structure, companies determine its "should cost"—what they believe they should pay for it.

The cost structure often includes:

Should costing enables professionals to compare supplier quotes with their own cost expectations. This understanding helps establish fair pricing and fosters collaborative relationships with suppliers.

Manufacturing cost analysis is essential to achieving reliable cost estimates and securing the best price for purchased parts. This involves breaking down the prices of individual components and comparing them to target costs to identify opportunities for optimization.

Should cost analysis takes a “bottom-up” approach, carefully evaluating all the materials, processes, and service costs involved in production. By adding these elements, organizations can determine the accurate “should cost” of a manufactured product.

This process requires cross-functional collaboration across teams, including product development, production, cost engineering, and supply chain teams.

Skilled cost engineers are central to this effort. They focus on identifying and prioritizing the most critical cost drivers. By analyzing these components and acting quickly on their findings, organizations can lower costs and speed up the launch of new products.

.png?width=1000&height=508&name=Design%20ohne%20Titel%20(92).png)

Implementing a robust should cost model delivers measurable benefits in procurement, cost management, and overall business performance. Here’s how it adds value to organizations:

Improved Cost Control & Transparency

Clear visibility into costs and real-time data ensures better planning and swift decision-making.

![]()

Strengthened Negotiation Leverage

Data-driven insights help identify overpriced components and secure fair pricing with suppliers.

![]()

Efficient Development &

Procurement Processes

Quick cost estimates and streamlined processes reduce development times and improve efficiency.

![]()

Enhanced Supplier Collaboration

Collaborating with suppliers builds trust, aligns methods, and drives joint cost-reduction efforts.

Should cost modeling is challenging due to its complexity and the required collaboration. Here are the main obstacles that complicate purchasing processes and cost engineering:

A strategic approach, combined with the right should-cost modeling tools, can help address these challenges and pave the way for more efficient purchasing processes.

ENTERPRISE PRODUCT COSTING:

THE KEY TO EFFECTIVE SHOULD COSTING

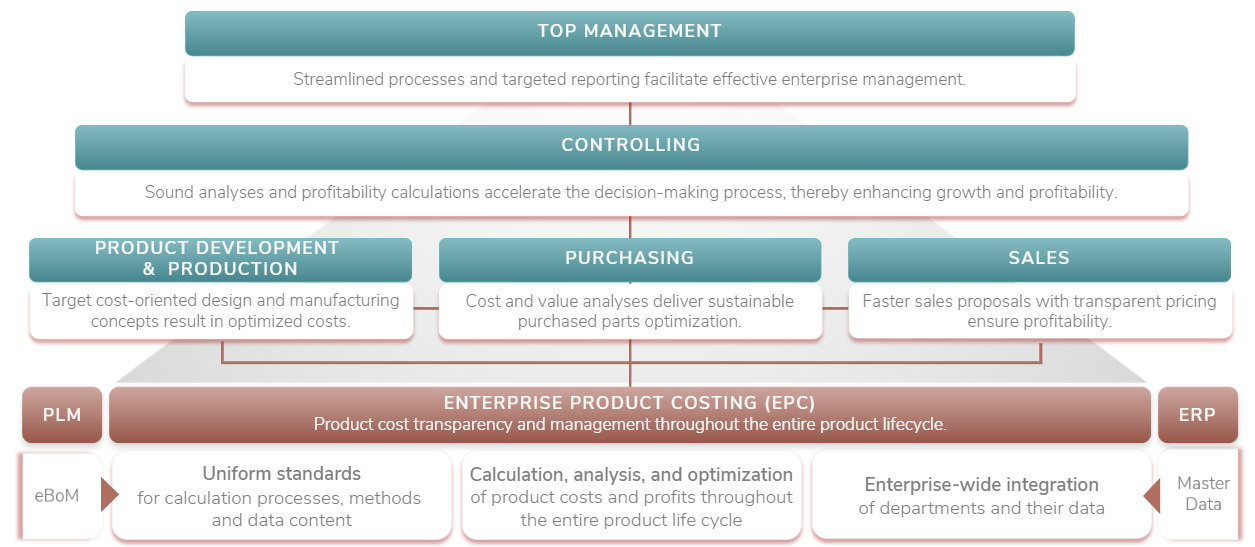

Enterprise Product Costing (EPC) is a method to consistently manage and control costs at every stage of a product's lifecycle.

Effective cost control begins by engaging all relevant business units from the start. Collaboration kicks off as early as the development phase, laying the groundwork for accurate results.

Calculations must be consistent across all business units and locations. This consistency is achieved by using the same data and methods every time.

This is why enterprise product costing brings together key departments—Development, Production, Purchasing, Sales, Controlling, and Top Management—ensuring seamless collaboration and alignment throughout the process.

Advantages of FACTON EPC Should Costing at a glance

Should cost models are inherently imprecise due to the complexity of cost drivers.

Should costs are estimates of the ideal cost for a product or service. They are calculated based on the efficient use of resources such as materials, labor, and overhead. Should costs help businesses identify cost discrepancies and uncover opportunities for savings.

A Should cost model is a structured framework or tool used to calculate the estimated cost of a product or service. This model breaks down costs into categories—like materials, labor, and overhead—and uses data-driven methodologies to provide transparency into cost drivers, enabling more effective negotiations and cost management strategies.

Professionals in procurement, cost engineering, and manufacturing benefit from leveraging this method to optimize decision-making.