Copyright © 2024 FACTON

Do you need to make a short-term investment in purchasing to increase profitability? With the FACTON EPC Should Costing solution and our partner umlaut manufacturing companies can achieve price reductions of at least 10% in purchasing within the shortest time and parallel optimize workflows and processes in procurement.

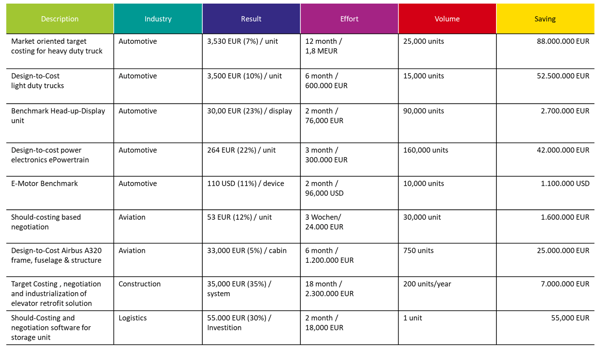

The combination of umlaut's consulting experience from more than 100 value engineering and cost reduction projects and FACTON's calculation software enables purchasing divisions to benefit from a profound price analysis of purchased parts.

Work in the future with a consistent calculation process which allows early determination and permanent optimization of product costs. Increase your cost transparency and reduce supply chain costs.

Due to cloud ability of FACTON EPC Should Costing companies are ready for operation within the shortest time. Umlaut supports customers with cost breakdown for purchased parts and preparation of negotiation workshops with suppliers.

Start the project today and use:

Implementation examples from Design-to-Cost programs in various industries starting from identification up to implementation

Value analysis: optimization of product value based on efficient services.png?width=600&name=umlaut-value-analysis_example%20(2).png)

Read more about umlaut and their cost engineering approach: https://www.umlaut.com/en/buzz-topics/cost-engineering

Read more about using the FACTON EPC Cost Model Designer in our EPC Should Costing solution.

Identify optimization potential, sharpen competitive edge

Learn in the webinar video how Purchasing benefits from the FACTON EPC Cost Model Designer